PRODUCTS

- Griege Fabric Inspection Machines

- Finished Fabric Inspection Machine

- Italian Design Inspection Machine

- Knitted Fabric Inspection Machine

- Technical Textile Inspection Machines

- Fabric Rolling Machine

- Fabric Folding Machine

- Greige Preparatory Machines

- Automatic Roll Packing Machine

- IGS-Inspection & Grading Software

- Garment / Made-Up Machines

- Project Turnkey

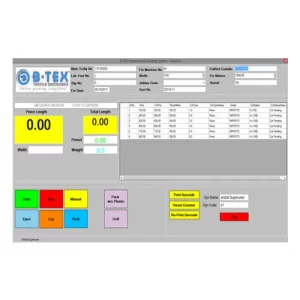

4 Point Software - Fabric Inspection Software

IGS is a software designed to grade the fabric quality as per 4 Point System. It helps to obtain maximum first quality fabric with minimum wastage by Mapping Module, Optimisation Module and Auto-Cut modules. Thus resulting in High 1st grade production, minimise wastage, optimised cutting and reduce labour.

Features:

- 4 point defect logging system

- Real-time piece map and defect concentration graph

- Automatic fabric grading

- Operator performance data

- Interfaces for machine run/stop and speed control, printer, scale, barcode scanner, keyboard, …

- Entry of defect codes including severity, width and position.

- Integration with Existing ERP or SAP

- Easy Fabric cutting Optimisation

- High quality Touch screen monitor with in-build PLC

- Online Report generation on basis of customer, order, quality, design, meter, etc.

Mapping Module(Greige Fabric Inspection)

Defects can be logged in Mapping Module as per 4-point system and later these are automatically loaded to server for optimisation. This works perfectly with our fabric Inspection machine Model : BIM-ABB+ABB (Mapping Machine) where fabric is feed in Big-Batch and after mapping it is delivered in Big-Batch

Model: Desire

Optimisation Module

In Optimisation Module, IGS Software suggest cut plan and still In-charge can optimise the fabric roll as per customer requirements and grade the quality to achieve maximum 1st quality rolls for final cutting and packing. Final cut plan and report can be send to customer or dept. head for approval

Auto-Cut Module

Auto-Cut Module cuts the fabric as per optimised cut plan. It generates sample, folder and reports with barcode printing and labelling.

Model: Nirvana

More than a software it works like a robot with our High-tech Nirvana Model, where IGS automatically controls the machine, cuts at specific length, removes waste and Stitch, generate and collect samples with barcode label, packs the rolls in Auto-CutPack with Plastic wrapping and sealing, later it transport the rollers through conveyors and finally sort in different trolley as per customer, design, quality, defects, etc.